CONTACT AN EXPERT

Blow molding machines

At SIDE, our aim is to provide swift and personalised responses for each individual client, based on the characteristics of their products, guaranteeing the best use and commercialisation of the said product.

The simplicity of our PET preform blowers, their versatility in application and their reliability, along with the latest technology and special care that we take over productivity and efficiency, make our products the benchmark in the bottles and PET containers market, in terms of quality and versatility.

All of this has earned us the trust that our clients place in us, and we have been able to grow with them, today making our company an established presence at international level.

Equipment

The constant evolution in the world of plastic containers, especially PET containers, requires new solutions every day.

At SIDE we are prepared to respond to the specific needs of each client, with definitive solutions to each case, attending to every small detail. This includes providing preform blowers for other plastics such as polythene, polypropylene, and bio-resins.

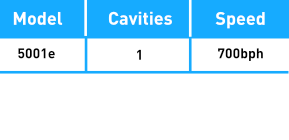

To help you find out which of our PET preform blowers is most suitable for your needs, the following comparisons table will give you access to the statistics for all our PET preform blowers.