NEW GENERATION OF SBM PET

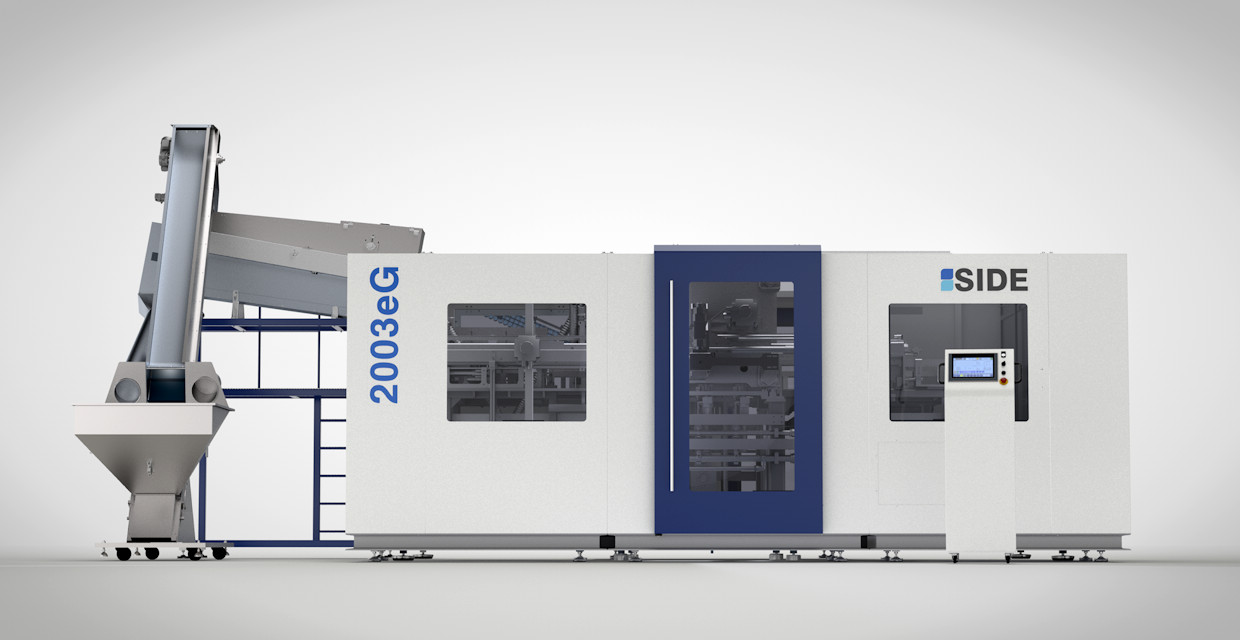

NEW HOUSING, IMPROVING THE ERGONOMY

The new housing gives more space and improves the accessibility to all the areas of operation of the bottle blower, making operation and maintenance easier. Reducing the time spent on these functions and also improving the ergonomics of the job.

Easier than ever to operate and to maintain

- Sliding doors with safety sensor chips

- Ergonomic workstations

- Elimination of blocking elements

- Movable mounting for the screen

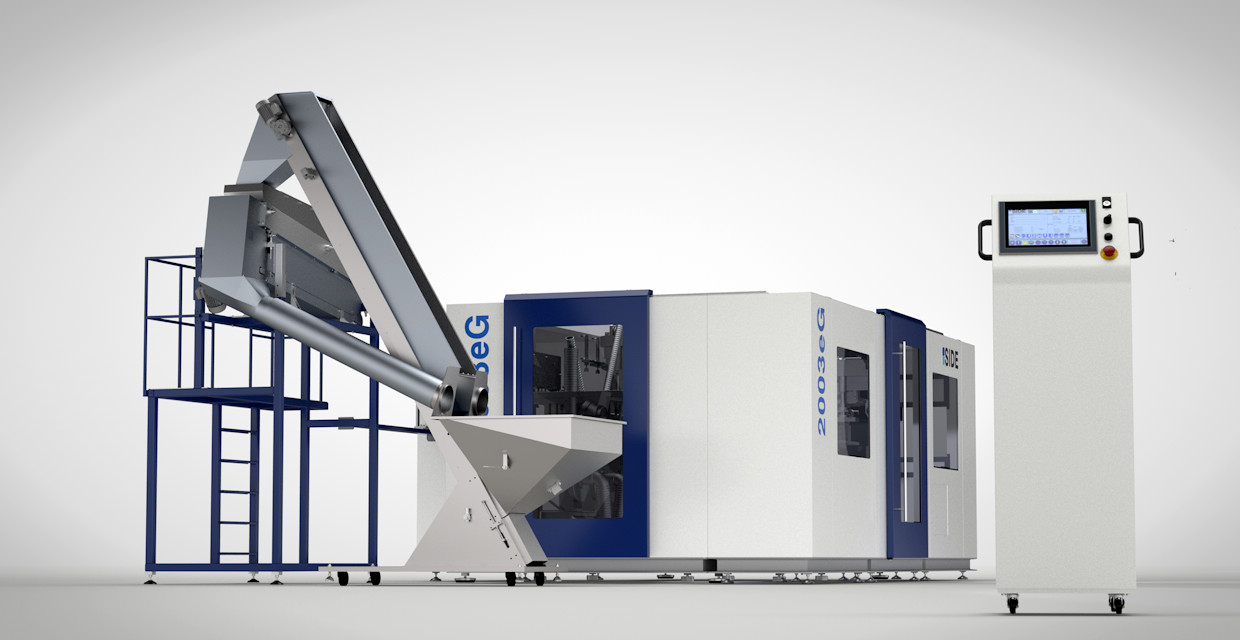

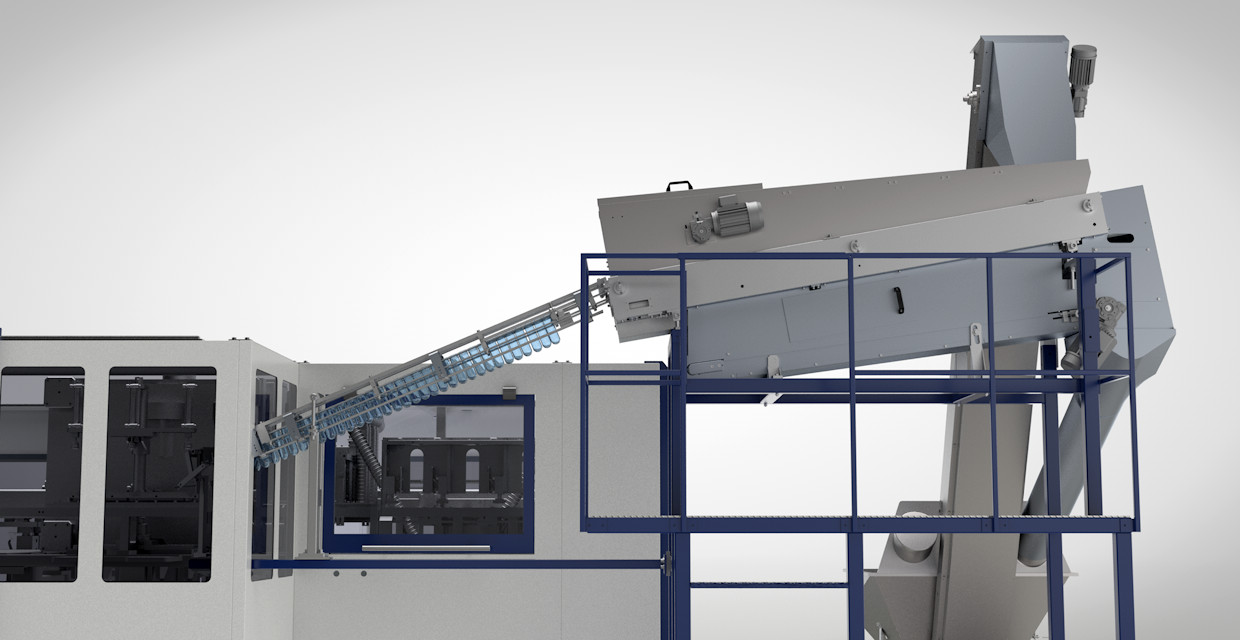

NEW WORKSTATION AND LOADING SYSTEM

Workstation in the preforms loader. The new loading system for preforms comes with a workstation, accessed by a fixed ladder, to improve access to the loading area, making maintenance and cleaning easier and improving the visibility of the whole preforms loading area. This workstation also has protection bars to prevent falls.

Now you can work without losing control over production

- New preforms turning system

- Elevated workstation

- Individual attachment system for preforms

- Easy access for cleaning and maintenance

GREATER PRECISION OF THE ELECTRONIC SYSTEM

The program has been updated, allowing working with smaller movements, especially in the press area: this enables the working life of some parts to be extended, reducing maintenance costs.

The new generation of SIDE bottle blowers uses SIEMENS controllers for the oven lamps, which enables the range of information given to the PLC to be expanded and also improves the process of preheating the preforms.

The electrical distribution boards have also been renewed, incorporating new ABB VSDs, improving the performance of the motors.

We have increased the precision of our blowing process, the key element of our equipment

- Update of the internal software processes

- New Siemens heater control

- New ABB inverters