In the PET bottle blowing process, the main electricity consumption occurs in the heating of the preforms, which has a direct impact on quality, production speed, and consumption. SIDE have implemented an innovative heating system, using low consumption lamps specifically developed for our sector.

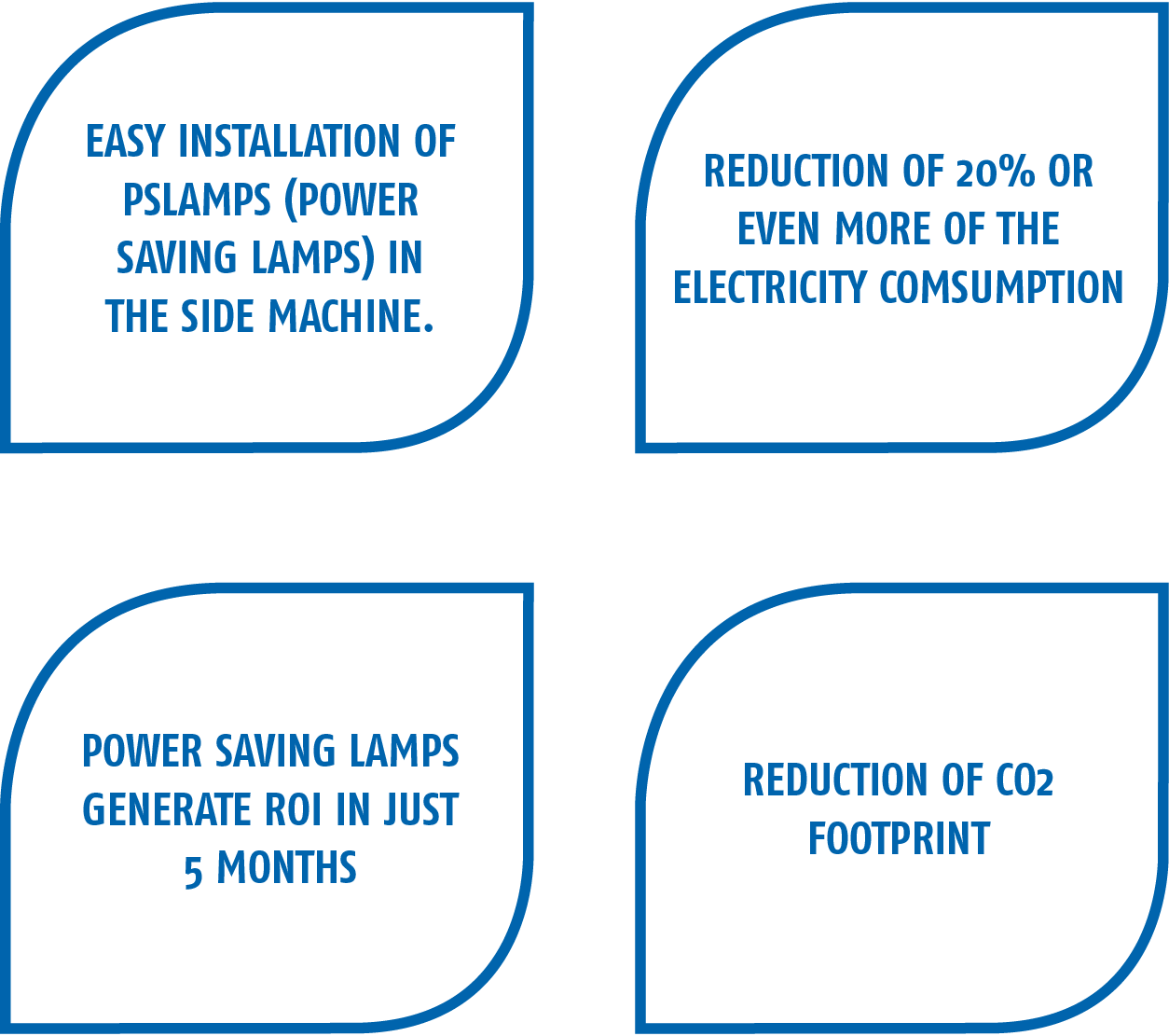

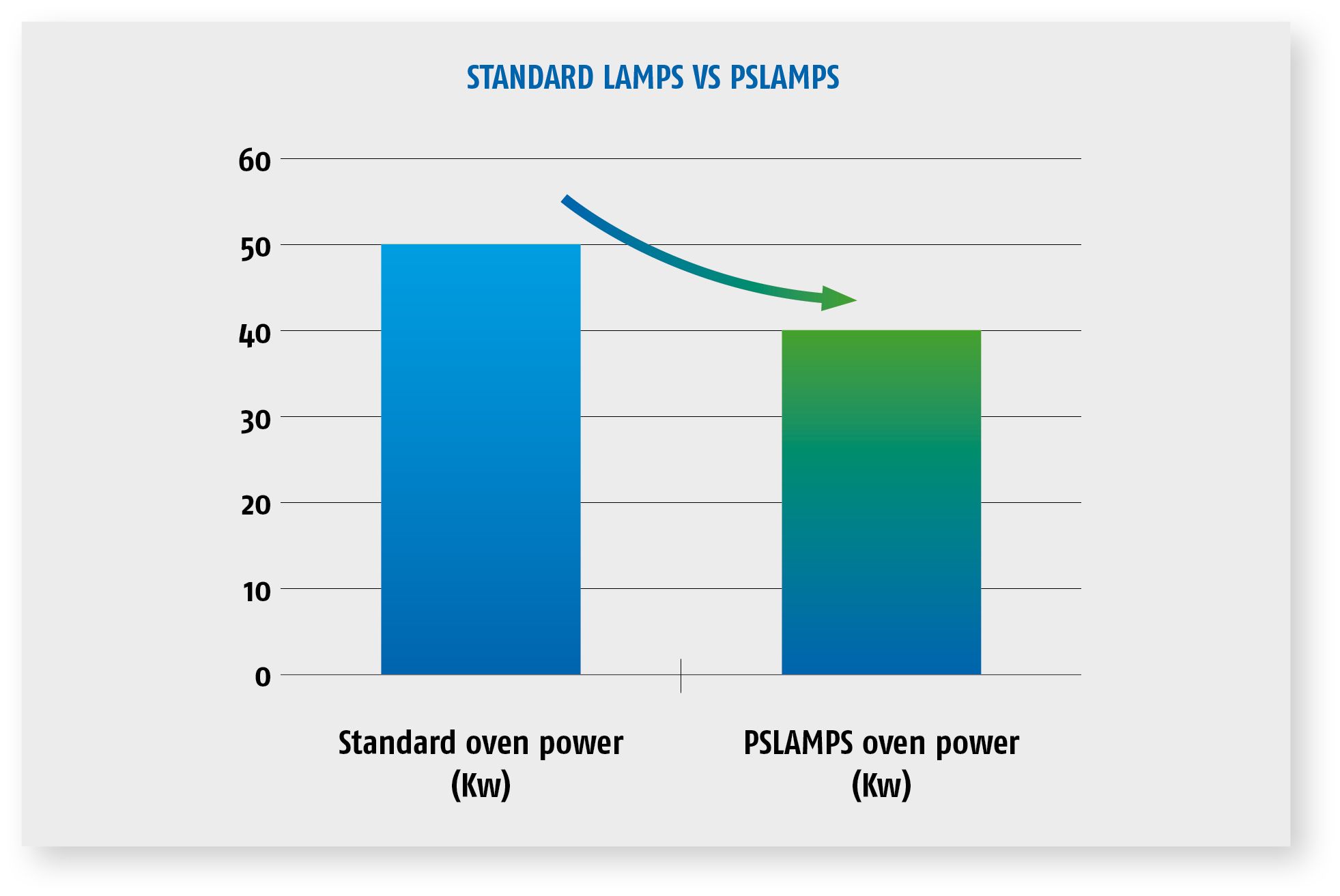

We achieve a reduction of 20 % or even more of the electricity consumption by the oven for our blowmoulding machine, helping to reduce the CO2 footprint as well.

The profitability of this solution is clear, and a return on investment can be achieved in a very short time, depending on the product, production hours, and kWh cost.

The profitability of this solution is clear, and a return on investment can be achieved in a very short time, depending on the product, production hours, and kWh cost.